In this video, We walk you through the step-by-step process of modeling an air cooler (fin-fan exchanger) in Caesar II, covering key aspects of piping stress analysis.

Struggling with pipe thickness calculations? This video is your ultimate guide to using ASME B31.1 (Power Piping) and B31.3 (Process Piping) codes. We break down the formulas, explain key parameters, and provide step-by-step examples in both imperial and metric units. Whether you're a seasoned engineer or a student, this tutorial will help you design safer and more efficient piping systems. Don't forget to like, comment, and subscribe for more engineering content!

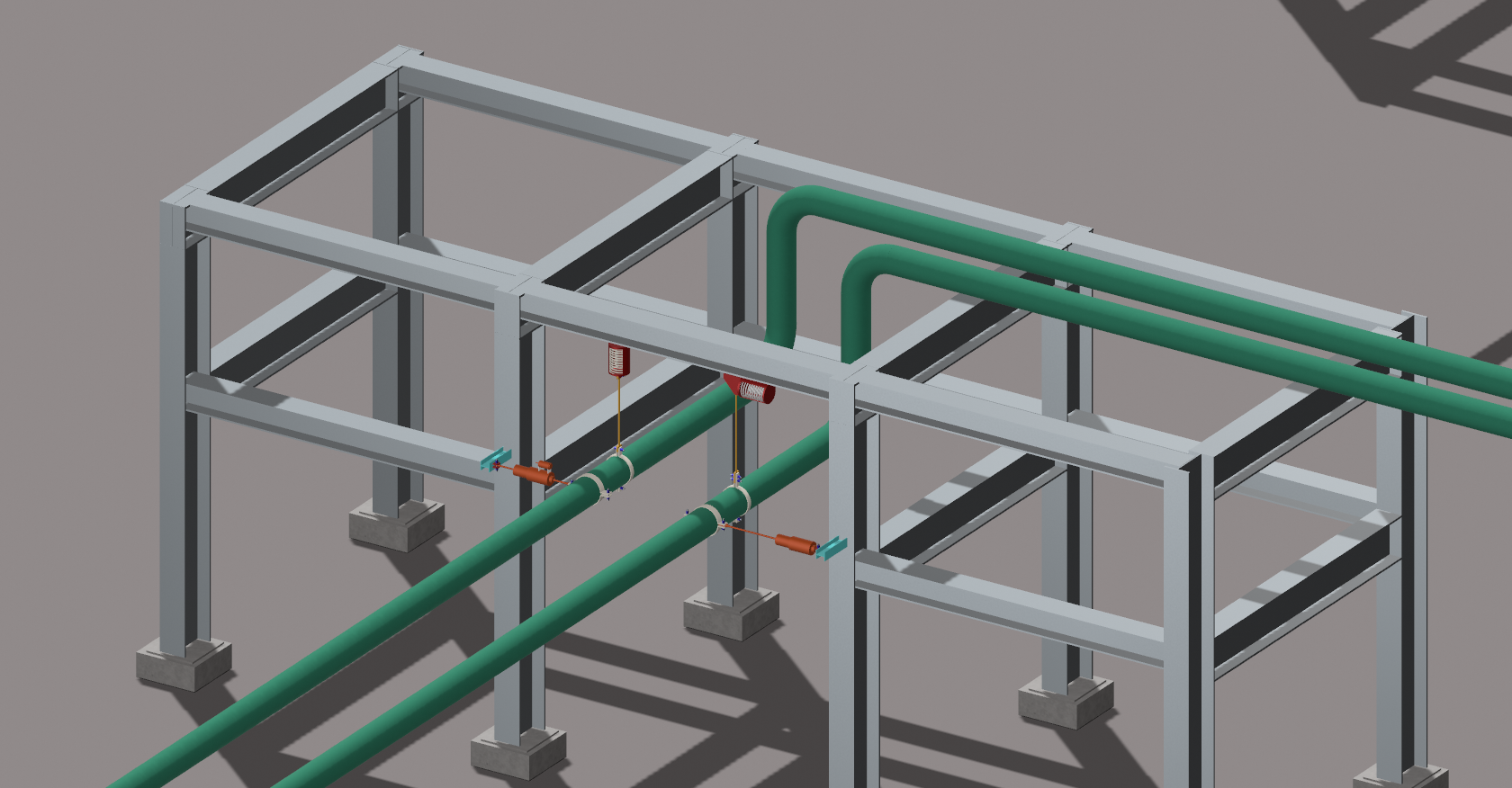

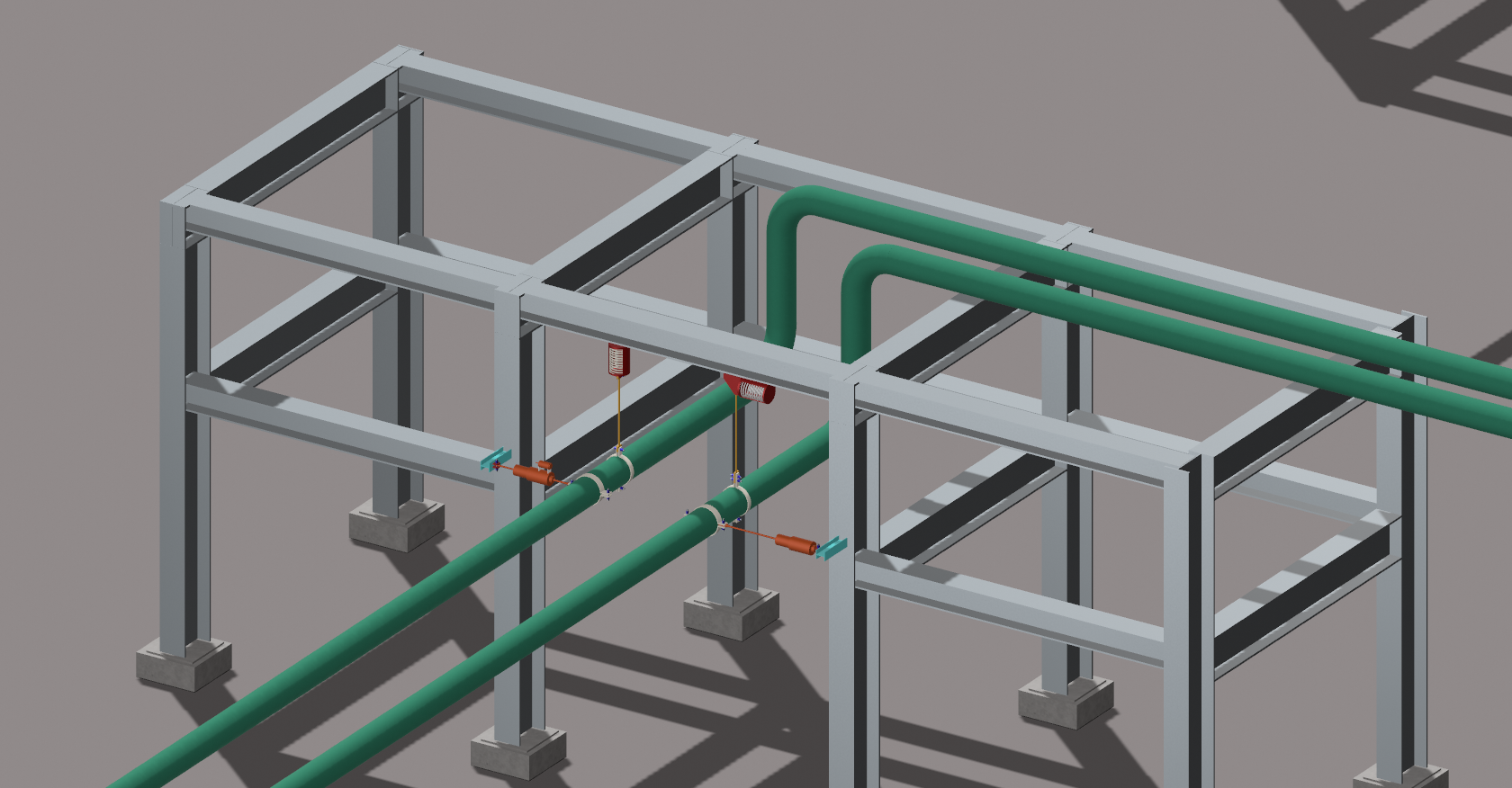

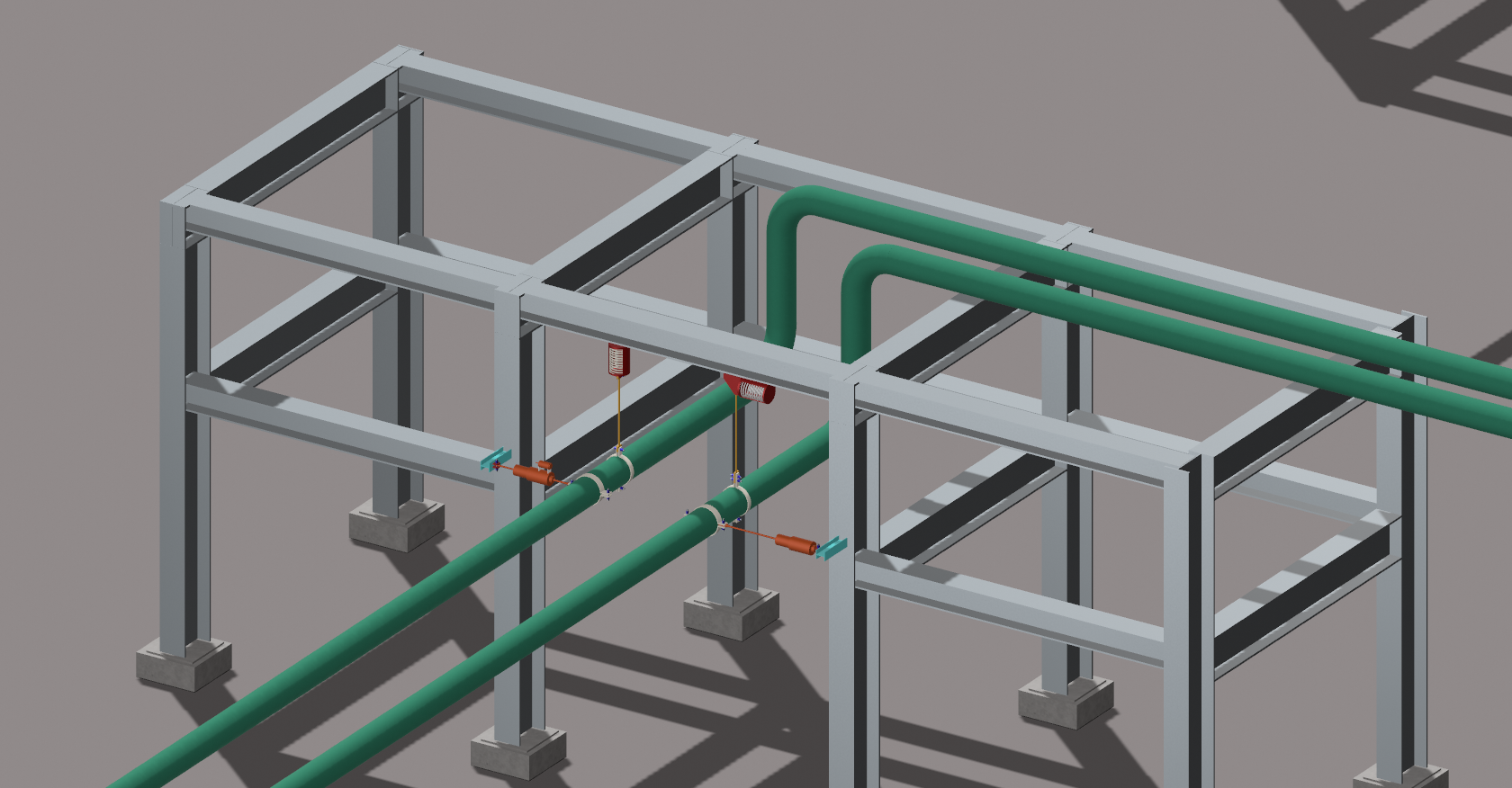

This video contains the answers about the need for expansion loop requirements. This will be done by using Caesar II Software, and also, at the end, we compare it with hand calculation.

In this video, I take you through a detailed analysis of horizontal vessel piping systems in CAESAR II, covering five scenarios. This video combines theoretical knowledge with practical applications to enhance your stress analysis expertise. Gain practical insights and tips to handle these conditions effectively and ensure code compliance in your piping systems.

In this video, we dive deep into the crucial relationship between piping restraints and pipe racks in industrial plants. Learn about essential factors like load transfer, thermal expansion, restraint selection, and code compliance to ensure your design achieves structural stability and operational reliability.

Thermal expansion is a critical concern for piping systems, but there are proven ways to address it effectively. In this video, we discuss the main issues caused by thermal expansion and present three practical solutions: designing expansion loops, installing expansion joints, and rerouting piping. Stay ahead of piping stress issues with these engineering tips!

Dive into an in-depth look at piping stress analysis using a real-world design! In this video, we explore key aspects of supporting piping systems connected to pressure vessels and air coolers, including spring hangers, guides, and strategic loops. Learn how each support type minimizes stress on equipment and enhances operational safety.

Learn from an experienced stress engineer about the importance of considering pressure vessel shells in your piping design. This video covers the consequences of ignoring vessel-piping interactions, including fatigue, creep damage, and support system overload. Plus, get practical tips for stress analysis, support design, and ensuring long-term reliability.

Are you a piping stress engineer? Avoid these 5 common mistakes that can derail your projects and lead to costly errors. Subscribe to PipingStress.Net for more insights into piping stress analysis, design, and best practices!

Efficient and safe equipment spacing is the backbone of industrial plant design. From tanks to pumps and heat exchangers, we explain how proper spacing enhances safety, minimizes risks, and ensures easy access for maintenance, all while staying compliant with industry regulations.

This video includes an actual pump station consisting of pumps, a tank, piping, and a pipe rack. It shows how the piping system is properly supported as per code requirements.

Thinking about a career in piping stress engineering? In this video, We break down the education, skills, and industry standards you'll need to get started. Learn how to navigate the path to becoming a successful piping stress engineer.

In this video, we explore the crucial aspects of stress analysis for fire-water piping systems in industrial environments. From thermal expansion to support design, discover how to protect your piping network and equipment nozzle.

This video explains reboiler piping stress analysis using clear and concise animations. Understand the principles and practices needed to analyze and mitigate stress in reboiler piping systems.

Our latest video breaks down the fundamentals of flare piping, focusing on flare headers, pressure safety valves or relief valves (PSV), and atmospheric vent designs. Enhance your knowledge and stay ahead in the industry with this informative guide.

Join us for a walk-through of the best practices for conducting a piping hydro test. This video covers everything from the test method and necessary equipment to water quality criteria and the recommended number of personnel. Gain insights into the complete hydro testing process and ensure that your tests are effective and safe.

Witness the application of engineering principles in gas outlet piping stress analysis. We showcase real-life examples and explain the technical aspects that ensure system integrity and safety. Perfect for engineers and students looking to enhance their understanding of piping stress analysis.

Learn how to calculate pipeline lowering into a trench with this comprehensive engineering tutorial. We break down the process into easy-to-follow steps, ensuring your following pipeline projects succeed. Subscribe for more engineering insights and practical how-to guides!

This video provides fundamental information about air coolers (air-cooled heat exchangers) and design considerations. It also covers piping design and piping stress-related issues explanations. Pros and cons of vendor-designed and contractor-designed air coolers are compared.

This video includes fundamental information about storage tanks and provides information on how to make piping design in terms of piping stress analysis. The video also shows the equipment's behavior during operation and the life span of the tank. And finally, you will see the use of spring supports for storage tank piping.

This video is prepared to explain the details of piping expansion loop calculation and design details. The video also contains a formula for an expansion loop for hand calculation. In the end, we summarised the tips on expansion loop design details.

This video explores how pipe rack design starts and how pipe rack design can improve piping system performance by maximizing space utilization, minimizing structural interference, and optimizing accessibility for maintenance and operation. Also, you will find some tips to reduce possible issues during the detailed piping design process. Additionally, you will see some suggestions for construction, maintenance, and operation.

This video contains information about piping stress engineering software.

This video is prepared for piping designers, engineers, piping stress engineers, and students to recommend the #5 most popular and useful books on piping design and stress analysis. The recommended books are also for pipeline designers and engineers.

In this comprehensive video, we delve into the intricate world of spring supports within industrial piping systems. Whether you're a seasoned engineer or an aspiring enthusiast, this guide will equip you with the knowledge needed to understand, select, and utilize spring supports effectively. The spring support is a commonly used device by piping stress engineers. This is why, it is the most important topic to be known by piping stress engineers.

This video contains the list a piping stress engineer must follow for each calculation and stress analysis. The piping stress engineer's checklist consists of 2 categories, before and after the analysis. Both of them include essential items and questions. You will learn when and why you should talk with other discipline engineers like process engineers and piping engineers. Also, some details are available about slug flow lines' pipe support.

This video includes fundamental information by Piping Stress Engineering.

This video includes fundamental information about pressure vessels required for piping stress engineering. This information is essential to understanding the behaviors of a pressure vessel. Supporting the pipes starts from the knowledge about the equipment behaviors.

This video including horizontal vessel's behaviors under operation temperatures. Also this video explains piping design in terms of piping stress analysis. You will understand how to locate the support and their attachments (stopper and guide).

This is the first video for the “Pressure Vessel" playlist. This video includes how to approach stress analysis on a pressure vessel connection or pressure vessel nozzle. The tricks are included to start piping stress analysis on a pressure vessel.

In this video, the results of different expansions of piping and pressure vessels have been analyzed. Additionally, pipe support locations have been assessed. You will learn about piping stress analysis tricks within this video.

IFigure out the external forces (wind, seismic, and operating temperature) that a pressure vessel is exposed to. This is important for piping stress engineers to prevent the nozzle and piping from overstressing. A pressure vessel displacement is an essential item that must be identified.

In this video, liquid Outlet and Gas Outlet nozzles are analyzed. The piping design connected to these nozzles must be carefully analyzed in terms of piping stress. Pipe support attachments like stoppers and guides must be used to prevent the nozzles from excessive forces and moments. A piping stress engineer should learn how equipment behaves prior to starting a piping design.

Considering the heat exchanger displacement due to different average temperatures. You will understand the fundamental approach to nozzle displacements on shell and tube heat exchangers. A piping stress engineer should calculate the nozzle displacements before piping stress analysis.

Elevated Pressure Vessel (Column) Piping Design and Stress analysis deserve utmost care. The Piping Stress Engineer should prevent the nozzle, shell, and piping from overstressing due to thermal expansion. This video contains an example of a column that includes a piping design that was completed by a piping designer. However, a piping stress engineer should analyze the design and minimize the loads on the nozzle and stress on the piping.

In this video you will understand why we call "Pound" for the flange classes. Flange rating is defined by pound per square inch. This is the most famous word in use in piping design and engineering world. The historical benchmark condition is being compared with ASME B16.5 and Table 2-1.1.

This video includes piping design in accordance with piping stress analysis for the shell inlet nozzle of a heat exchanger. You will learn how to support the piping according to the exchanger’s behavior. This will help you to start your stress analysis from the right point, which will save time and minimize any mistakes.

This video contains a piping stress analysis of the heat exchanger's tube inlet piping. You can understand how to route the piping, how to support the piping, and where to place a stopper on the line in accordance with the stress analysis. The video is animated video for better understanding by everyone. It is important for us to teach the piping engineering learners about starting a piping design from the right point, otherwise, you will lose time during the piping stress analysis.

This video contains information about international standards of centrifugal pumps, types of centrifugal pumps, thermal expansion of centrifugal pumps and calculation details of pipe nozzle loads. This video is an introduction for the next videos that will include piping design as per piping stress analysis.

This video gives piping design details for a centrifugal pump by piping stress analysis. If you want to learn how to finalize your piping design for a pump, this video is for you. Also, you will see where to locate a centrifugal pump in a plant. Discharge and Suction nozzles' piping design and stress analysis are assessed separately. And finally, you will see a comparison of two different pump piping designs. Advantages and disadvantages are listed in that comparison section.

This video contains pipe support and restraint information essential to knowing by piping engineers, especially piping stress engineers. You will learn the details of pipe span calculations as well. The video contains the type of pipe shoes and their usage by design conditions (pipe size and operating temperature limitations).