PIPING STRESS AND SUPPORT ENGINEERING BLOGS

PipingStress.Net contains blogs and various video content about Piping Stress Engineering. Detailed information about pipe support and pipe restraints are essential subjects mentioned in our blogs and videos.

The blogs also contain information about international codes and applications in the Oil and Gas Industry. In addition, you will see the equipment behaviors under operation pressure and temperature in our videos by the provided links. These videos are animated videos for a better understanding of the technical issues.

Please write your request to us from the contact page, if you want to learn about any special subject.

Welcome to our immersive hub of knowledge, where the intricate world of piping stress and support engineering comes alive through vivid visuals and expertly crafted animated videos.

Our blog is a treasure trove of insights, designed to demystify complex technical details and empower enthusiasts and professionals alike.

Visual Brilliance: Dive into the technical intricacies of piping systems with our extensive collection of photos and sketches. Each visual is carefully curated to offer a deeper understanding of the principles driving piping stress analysis and support engineering. Whether you're a seasoned engineer or a curious learner, our visuals are your gateway to a clearer comprehension of these critical concepts.

Animated Revelations: Experience a new dimension of learning through our animated videos. Prepared by our experts, these videos provide dynamic insights into the dynamic forces at play in piping systems. From thermal considerations to support engineering strategies, our animations bring theory to life, making it accessible to all levels of expertise.

Calculating Seismic g-value for Caesar II Using ASCE 7

In Caesar II, seismic loads can be defined using g-values, which represent the acceleration due to gravity as a fraction or multiple of the gravitational acceleration (9.81 m/s² or 32.2 ft/s²). The g-value is a critical input for seismic analysis, as it determines the magnitude of the seismic forces applied to the piping system. Here's how you can determine the appropriate g-value for your analysis:

How to Find a Job as a Piping Stress Engineer?

Piping stress engineering is a specialized field in the oil & gas, power, chemical, and petrochemical industries. With the growing demand for safe and efficient piping systems, skilled stress engineers are in high demand. However, securing a job in this field can be challenging, especially for beginners.

In this guide, we’ll explore the steps to finding a job as a piping stress engineer, from required skills to job search strategies.

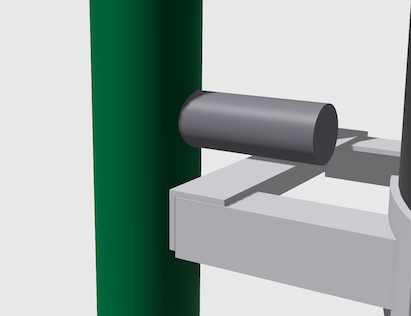

Trunnion Support (or Dummy) Check

Trunnion supports are among the most frequently used pipe supports in the process piping industry. This support is widely used in the piping industry due to its ease of construction and erection. The construction and erection of a dummy supports is very easy because you have to simply weld a pipe (normally one or more size less than the parent pipe to which it is to be welded) with the parent pipe. However, the load-bearing capacity of these supports is not as comparable to civil supports. So, every stress engineer must check the weld point from a failure viewpoint and investigate the ability to carry the piping load (mostly the tangential and longitudinal load and corresponding moment). The chances of weld failure increase with an increase in trunnion length or trunnion height.

Digital Twin & Piping Stress

A digital twin is a virtual model of a physical asset, system, or process that uses real-time data and simulations to mirror its real-world counterpart. In piping design and stress analysis, digital twins combine data from sensors, CAD models, and simulation tools to provide a comprehensive and up-to-date view of a piping system’s performance, structural integrity, and potential risks.

Future Trends in Piping Stress

Piping stress engineering is a critical field ensuring the safety, reliability, and efficiency of piping systems in industries ranging from energy to manufacturing. With rapid advancements in technology, materials, and industry demands, the landscape of piping stress engineering is set to undergo significant transformation.

Thermal Expansion in Piping

As a piping stress engineer, understanding thermal expansion and designing for it is vital to ensure system safety and reliability.

We’ll look at:

• How pipes expand under heat,

• The potential problems caused by thermal expansion, and

• Practical solutions using animations, including straight piping, expansion loops, expansion joints, and piping route changes.

What Does a Piping Stress Engineers Do?

A Piping Stress Engineer is essential in the design and analysis of piping systems, ensuring that these systems can handle operational stresses and forces. Piping systems are crucial to industries such as oil and gas, power generation, and chemical processing. The engineer’s role is to ensure the safety, reliability, and efficiency of these systems under various conditions.

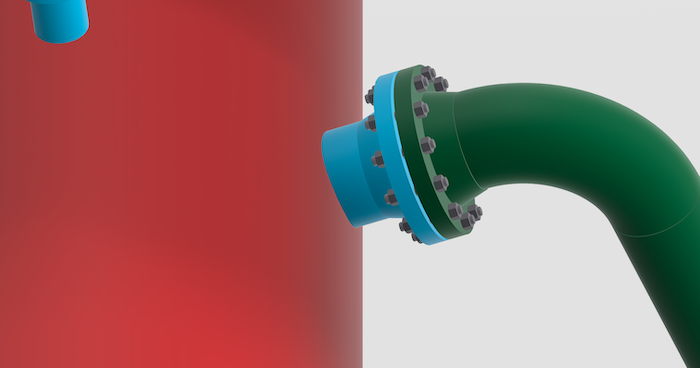

Pressure Vessel Shell in Conjunction with The Piping System

In industrial plants, the interaction between piping systems and pressure vessels is critical in ensuring operational safety and equipment longevity. Failing to account for the relationship between these two components can lead to significant problems, including mechanical failures, operational inefficiencies, and even hazardous situations.

Common Mistakes by Piping Stress Engineers

A flawless stress analysis certainly deserves the utmost care and attention when it comes to technical input, extensive knowledge, and practical experience. For a new piping engineer, it would be beneficial to read this informative blog post in order to learn about the common mistakes made in the field, which will ultimately help to enhance his or her overall experience and proficiency in performing stress analyses.

Right-Hand Rule

The Right-Hand Rule is a concept used in various engineering and physics fields, including piping stress analysis, to determine the direction of moments and forces, particularly in 3D coordinate systems. In piping stress calculations, it helps in understanding how moments and torques act on pipe systems when subjected to different loads, such as thermal expansion, pressure, or external forces.