Pipe Rack Design For Piping

Pipe racks are structures that carry pipes connecting process units and equipment. Additionally, pipe racks also carry electrical and instrument cables and the necessary supports for them. At the same time, air coolers can also be installed on pipe racks. Pipe racks are generally made of Steel but also can be made of concrete or a combination of concrete and steel structures.

Proper design of piping within pipe racks is crucial for ensuring operational efficiency, safety, and regulatory compliance. Because of the close relation with the pipe rack structure, the pipe rack design must be considered together with the piping design.

To design a pipe rack, we should have the P&ID, Flow Diagram, Plot Plan, Layout Specification, Client Specification, Construction Material of the Rack, Fire Protection Requirement, and equipment details to be located around the pipe rack.

Pipe Rack design starts from the designation of the width, bent spacing, and elevations. Determining all of these, we should prepare a line routing diagram. Please see an example of a line routing diagram.

WIDTH OF THE PIPE RACK

A line routing diagram shows us a preliminary piping routing between the equipment of the plant. The cross-section of the diagram should include all the pipeline’s cross-sections including line size, insulation, and line number. Line-specific information will help us to group the lines for process or fluid content and also help us to identify the width of the pipe rack.

In a large plant, lining up all the piping lines side by side would lead us to design a very wide pipe rack. However, this is neither financially nor technically correct. Therefore, we should group the pipes according to their systems. This grouping is generally done in the oil and gas industry as process and utility lines. Process lines are positioned at a lower elevation, while utility lines are located at an upper elevation. Top-level of the pipe rack is generally reserved for electrical and instrumentation cable trays. At an early stage of the process plant design, it is suggested to keep %10-20 space for the possible growth of piping lines during the engineering phase of the project.

Also at the end of the project, you may need to keep distance on pipe rack width for future extensions. All these are to be considered for the width designations of the pipe racks. Once the width of the pipe rack is decided, future growth should be carefully considered in terms of civil/structural requirements and cost impact. For example, the width would be 2 levels with 10m wide or 3 levels with 6m spacing.

A Typical Pipe Rack Section View

A line spacing chart is to be prepared because it will be required for the additional line during future growth.

Please see the above figure of a typical pipe rack cross-section. There is a walkway on the top level for cable pulling during construction and also can be used for possible maintenance requirements. Additionally, this walkway can be used for accessibility during the operation. An access-way spacing is also considered under the rack because of the serviceability of the equipment located on the ground elevation.

BENT SPACING

Pipe spacing is one of the most important items to be considered if you are designing a pipe rack. Before deciding on the pipe rack column distance, the average line size is to be designated, and then, support spacing calculation is to be done as per the average size of the pipe. You can watch the previous video about the support spacing calculation.

The calculated support spacing will be used as guidance for choosing pipe rack column distance. For this, you should also consult with civil and structural engineers. Generally, 2 inches is the smallest size that is being used for pipe racks to avoid intermediate supports.

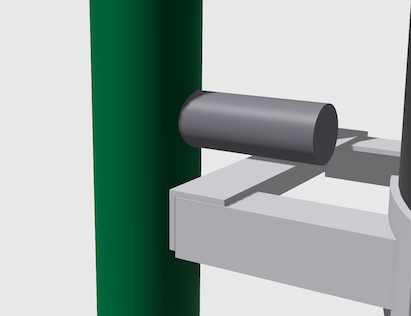

If the lines consist of flanges inside the rack, they should be located as staggered. Please see the below figure.

Staggered Flanges on Pipe Rack

PIPE RACK LEVELS (ELEVATION)

The minimum height of the pipe rack is to be decided according to the vehicle (crane, cherry picker, etc.) passed from the road under the pipe rack. Generally, the minimum height is 3600mm.

Determining the exit level above and below, the largest diameter’s 45-degree turn height is to be considered or the 90-degree turn height of the average line size can be considered. Please see the figure below. The exit level above and below the rack can be between 800mm to 1200mm.

PIPING DESIGN

EXPANSION LOOPS

It is essential to make a flexibility check of the lines lying on the pipe rack. For the details of the expansion loop you can check the blog post individually about the expansion loops.

FLAT TURNS

The use of flat turns should be avoided. If you want to change the sequence of the lines, a flat turn will not serve for this. Instead, you can choose the elevation difference method for the pipe rack turns. As you can see from the isometric view the change in sequence is practical.

SECONDARY PIPE RACK INTERSECTION

If two secondary pipe racks are connected to a main pipe rack, they should be staggered or located east of one bay because of the challenges of the branch connection design.

PIPE RACK EXTENSION

Any equipment can be located over the pipe racks. Pipe racks are generally fireproofed until the lower elevation but if there is equipment located over the pipe rack the fireproofing must be extended until the equipment supports.

A Piping designer should consider the thickness of fireproofing for piping design to prevent possible clashes.

During pipe rack design, future expansion should also be considered. Vertical risers should be kept away from the columns for horizontal expansions. Also, any piping line, cable tray, or support can not be located over the pipe rack column due to the future vertical expansion. The future expansion is not only for a pipe rack but also it would be an air cooler or heat exchanger.

In Caesar II, seismic loads can be defined using g-values, which represent the acceleration due to gravity as a fraction or multiple of the gravitational acceleration (9.81 m/s² or 32.2 ft/s²). The g-value is a critical input for seismic analysis, as it determines the magnitude of the seismic forces applied to the piping system. Here's how you can determine the appropriate g-value for your analysis: