PIPING STRESS AND SUPPORT ENGINEERING BLOGS

PipingStress.Net contains blogs and various video content about Piping Stress Engineering. Detailed information about pipe support and pipe restraints are essential subjects mentioned in our blogs and videos.

The blogs also contain information about international codes and applications in the Oil and Gas Industry. In addition, you will see the equipment behaviors under operation pressure and temperature in our videos by the provided links. These videos are animated videos for a better understanding of the technical issues.

Please write your request to us from the contact page, if you want to learn about any special subject.

Welcome to our immersive hub of knowledge, where the intricate world of piping stress and support engineering comes alive through vivid visuals and expertly crafted animated videos.

Our blog is a treasure trove of insights, designed to demystify complex technical details and empower enthusiasts and professionals alike.

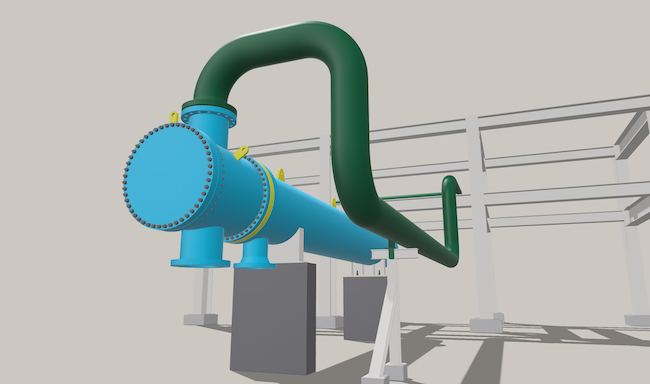

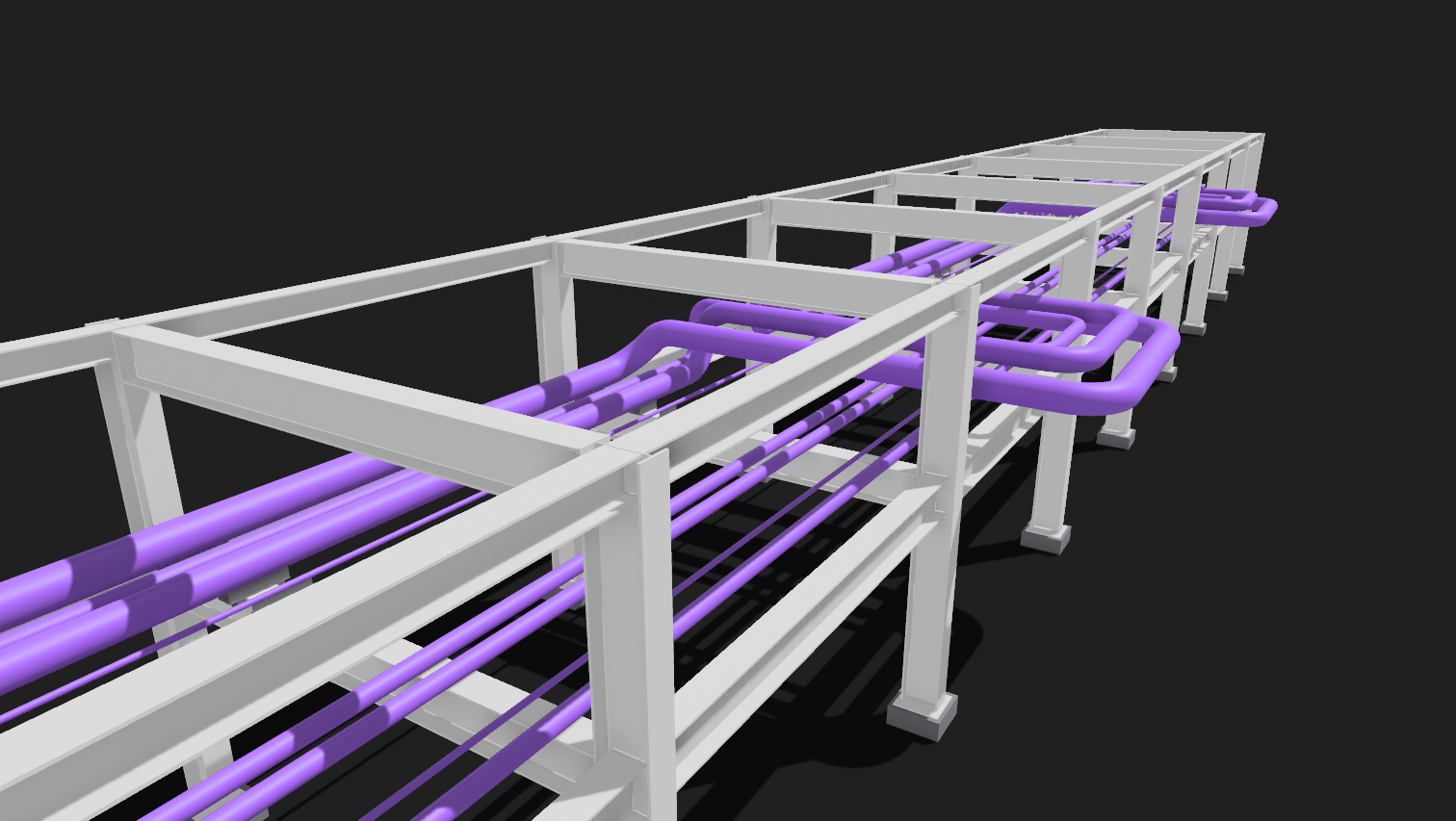

Visual Brilliance: Dive into the technical intricacies of piping systems with our extensive collection of photos and sketches. Each visual is carefully curated to offer a deeper understanding of the principles driving piping stress analysis and support engineering. Whether you're a seasoned engineer or a curious learner, our visuals are your gateway to a clearer comprehension of these critical concepts.

Animated Revelations: Experience a new dimension of learning through our animated videos. Prepared by our experts, these videos provide dynamic insights into the dynamic forces at play in piping systems. From thermal considerations to support engineering strategies, our animations bring theory to life, making it accessible to all levels of expertise.

How to Find a Job as a Piping Stress Engineer?

Piping stress engineering is a specialized field in the oil & gas, power, chemical, and petrochemical industries. With the growing demand for safe and efficient piping systems, skilled stress engineers are in high demand. However, securing a job in this field can be challenging, especially for beginners.

In this guide, we’ll explore the steps to finding a job as a piping stress engineer, from required skills to job search strategies.

Snubber - Shock Absorber

In industrial piping systems, snubbers, also known as shock absorbers, play a critical role in preventing excessive movement caused by dynamic forces like seismic activity and operational vibrations.

Column (Tower) Piping Stress Analysis

Column piping is located in conjunction with the tray nozzle and platform orientation. When possible, the piping is grouped for ease of support and positioned to accommodate interconnection with related equipment and the pipe rack.

Expansion Loop Design and Calculation Details

Expansion Loop Design and Calculation Details