Piping System Internal Cleaning

During the construction phase of industrial piping systems, cleaning methods are essential to ensure that piping lines are free from construction debris, dust, welding residues, and other contaminants that could affect the system's integrity and performance. Here are the primary industrial piping cleaning methods used during construction:

FLUSHING

CHEMICAL CLEANING

MECHANICAL CLEANING

HYDRODYNAMIC CLEANING

STEAM CLEANING

ABRASIVE CLEANING

PRE-OPERATIONAL CLEANING

A. Flushing

Water Flushing

Description: Water is pumped through the piping lines at high velocity to remove loose debris, dirt, and other contaminants. This method is generally used following a hydrostatic test of the line.

Application: Commonly used in water, oil, and gas pipelines.

Air Flushing/Bursting

Description: Compressed air blows out debris and dust from the pipelines.

Application: Also called Decompression air blow or Air shot blowing. This method is suitable for lines where water use is not advisable, such as those for transporting gases. Special safety precautions must be taken for this method. For example, a barrier in front of the nozzle is essential to prevent any hard object from blowing away.

Decompression air blowing can be applied to the piping systems, with the outside diameters 6” and above, following the pressure testing of the lines.

Compressed air shall be supplied by a temporary high-capacity oil-free compressor. A bursting disk shall be used to perform this method.

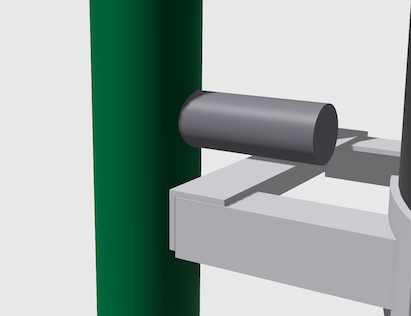

The bursting disk shall be positioned on the outlet flange (blowout flange) of the line. The disk contains a 2-3mm thick ring plate and several nylon sheets (Extruded Nylon Tecamid or similar).

The ring plate will be bolted to the outlet flange of the system. The nylon sheets will be positioned between the ring plate and the outlet flange (blowout flange). The quantity of the nylon sheets will differ from the pressure that will be applied to the piping system.

The air pressure in the system won’t be higher than 2 barg. A manometer shall be used to control the pressure.

The piping system will be isolated by valve closing or blinding the flanges on the test package limits except the blowout flange.

The line will be pressurised by one of the blind flange’s threaded hole. Once the line is under pressure the nylon sheet diaphragm of outlet flange (bursting disk) will swell and burst.

The bursting will be repeated until the cleanliness level is achieved. The cleanliness will be able to understand from the colour of the air outlet. A camera inspection can be used if required.

At the beginning the number of nylon sheets will be less but they will be increased by the pressure applied (not more than 2 barg).

Decompression Air Blow Bursting Disk

The bursting disk shall be positioned on the outlet flange (blowout flange) of the line. The disk contains a 2-3mm thick ring plate and several nylon sheets (Extruded Nylon Tecamid or similar).

Safety

The stopper, preferably made of scaffolding materials, is a crucial safety measure. It's placed in front of the bursting disk to control and prevent the dust and some pieces from being thrown far away from the outlet flange, ensuring your safety.

Safety barriers (soft barriers) shall be positioned in the area around the outlet flange in a 20m radius (during the release of air).

A horn shall be used before the blowout during swelling to warn the people working around the area.

Air blowing will take place after normal working hours.

The personnel involved in this activity and the squads working close to the area have to use ear plugs (in addition to the PPE used) to prevent themselves from the noise effects.

The air shot-blowing operation will be subjected to a specific work permit. A special Task Risk Assessment must be prepared to evaluate the risks of this activity.

Welding activities should be stopped during the execution of this process around the area (preferably in 150m diameter) to prevent possible weld defects because the welders can be scared of the sudden bursting sound.

Oil Flushing

Description: Oil is pumped through the line to remove debris, dirt, and other contaminants.

Application: The same type of oil is circulated inside the piping. This is generally applied to the lubrication system of big pumps or turbine compressors.

B. Chemical Cleaning

Chemical cleaning of industrial piping is a process that involves using chemical solutions to remove contaminants such as scale, rust, oils, grease, and other deposits from the internal surfaces of pipelines. This method is effective for ensuring the cleanliness and operational efficiency of piping systems in various industries, including oil and gas, petrochemical, power generation, and food processing. Here are the key aspects of chemical cleaning, including the requirements and the equipment needed:

Requirements for Chemical Cleaning

Assessment and Planning

Inspection: Conduct a thorough inspection of the pipeline to determine the type and extent of contamination.

Chemical Selection: Choose the appropriate chemicals based on the nature of the contaminants and the material of the pipeline.

Procedure Development: Develop a detailed cleaning procedure, including the concentration of chemicals, circulation time, and temperature requirements.

Safety Considerations

Material Compatibility: Ensure that the selected chemicals are compatible with the pipeline material to avoid corrosion or damage.

Safety Data Sheets (SDS): Review the safety data sheets for all chemicals to understand the hazards and necessary precautions.

Personal Protective Equipment (PPE): Equip workers with appropriate PPE, including gloves, goggles, and protective clothing.

Ventilation: Ensure adequate ventilation to prevent the buildup of hazardous fumes.

Environmental and Regulatory Compliance

Waste Disposal: Plan to properly dispose of used chemicals and residues in compliance with environmental regulations.

Permits: Obtain any necessary permits for the use and disposal of chemicals.

Equipment Required for Chemical Cleaning

Chemical Storage and Handling

Chemical Storage Tanks: These are used to store cleaning chemicals before and after use.

Chemical Feed Pumps: To accurately dose chemicals into the system.

Circulation System

Pumps: High-capacity pumps circulate the chemical solution through the pipeline.

Hoses and Fittings: Corrosion-resistant hoses and fittings connect the circulation system to the pipeline.

Heat Exchangers

Heaters: Heat the chemical solution if required by the cleaning process to enhance the effectiveness of certain chemicals.

Monitoring and Control Equipment

Flow Meters: To monitor the flow rate of the chemical solution.

Pressure Gauges: To ensure the system is operating within safe pressure limits.

pH Meters: To monitor the acidity or alkalinity of the solution.

Temperature Gauges: To maintain the required temperature for effective cleaning.

Waste Handling

Neutralization Tanks: To neutralize acidic or alkaline waste before disposal.

Filtration Systems: To remove solid particles from the waste stream.

Storage Tanks: These are for temporary storage of waste before disposal.

Typical Chemical Cleaning Process

Pre-Cleaning Preparation

Isolate the pipeline from the rest of the system.

Install temporary piping and circulation equipment.

Initial Flushing

Flush the pipeline with water to remove loose debris and check for leaks.

Chemical Cleaning

Circulate the chemical cleaning solution through the pipeline for a specified duration.

Monitor the process using pH, temperature, and flow rate indicators.

Rinsing

Rinse the pipeline thoroughly with water to remove any residual chemicals.

Perform neutralization if required.

Post-Cleaning Inspection

Inspect the pipeline to ensure all contaminants have been removed. Special camera systems can be used for internal inspection.

Restoration

Reinstate the piping system.

Dispose of used chemicals and waste according to regulations.

Common Chemicals Used

Acids: Hydrochloric acid, sulfuric acid, citric acid for removing mineral scales and rust.

Alkaline Solutions: Sodium hydroxide and potassium hydroxide remove grease, oil, and organic residues.

Solvents: Organic solvents like acetone and toluene dissolve tar and heavy hydrocarbons.

Detergents: Surfactants and detergents to emulsify and remove various contaminants.

Inhibitors: Added to acid solutions to prevent corrosion of the pipeline material during cleaning.

C. Mechanical Cleaning

Pigging

Description: A cleaning device known as a "pig" is sent through the pipeline to scrub the interior physically.

Application: Effective for removing construction debris, welding slag, and other solid contaminants.

Scraping

Description: Mechanical scrapers are used to manually clean the interior surfaces of the pipes.

Application: Used in larger diameter pipes where manual intervention is possible.

D. Hydrodynamic Cleaning

Hydro Jetting

Description: High-pressure water jets are used to clean the interior surfaces of the piping spools.

Application: Effective for removing stubborn deposits and ensuring a thorough cleaning.

Source of the photo: https://www.hammelmann.com/us/applications/cleaning-pipes.php

Source of the photo: https://www.hammelmann.com/us/applications/cleaning-pipes.php

E. Steam Cleaning

Steam Flushing

Description: Steam is introduced into the piping lines to clean and sanitize the interior surfaces.

Application: Used in industries requiring sterilization, such as food processing and pharmaceuticals.

F. Abrasive Cleaning

Sand Blasting

Description: Abrasive particles are blasted through the piping spools to remove rust, scale, and other contaminants.

Application: Effective for preparing pipe surfaces for coatings and further treatments.

Ice Blasting

Description: Use ice pellets as the abrasive medium to clean the interior surfaces.

Application: Leaves no residue as the ice melts, making it suitable for industries requiring high cleanliness levels.

G. Pre-Operational Cleaning

Passivation

Description: A chemical process that creates a protective oxide layer on the surface of the pipe to prevent corrosion.

Application: Common in stainless steel piping used in chemical and food processing industries.

Biocide Treatment

Description: Biocides are used to eliminate any microbial contamination that may have occurred during construction.

Application: Essential for pipelines in water treatment, food processing, and pharmaceutical industries.

Best Practices

Inspection: Before cleaning, inspect the pipelines for any large debris or obstacles that could impede cleaning.

Sequencing: Follow a logical sequence of cleaning methods to ensure thorough removal of contaminants (e.g., flushing before chemical cleaning).

Safety: Ensure all safety protocols are followed, especially when using chemicals or high-pressure equipment.

Documentation: Keep detailed records of the cleaning process, including the methods used, the chemicals involved, and the inspection results.

Summary

Choosing the right cleaning method during construction depends on the piping line material, the contaminants' nature, and the specific industry requirements. Employing the appropriate methods ensures the pipelines are clean, safe, and ready for operation, thus preventing potential issues and prevent equipment damage.

In Caesar II, seismic loads can be defined using g-values, which represent the acceleration due to gravity as a fraction or multiple of the gravitational acceleration (9.81 m/s² or 32.2 ft/s²). The g-value is a critical input for seismic analysis, as it determines the magnitude of the seismic forces applied to the piping system. Here's how you can determine the appropriate g-value for your analysis: